Mkpanaka Piston S45C Hard Chrome Plated Maka Cylinder Pneumatic

A na-akpọkwa mkpanaka pneumatic cylinder hydraulic piston mkpanaka chrome plated.Ọ bụ mkpanaka nke nwere elu na-agwọ ya site na igweri pụrụ iche na plating chrome siri ike.A na-eji ya n'ọtụtụ ebe dị iche iche cylinders, hydraulic cylinders, packing, woodworking, spinning, printing and coloring machines, die-casting part and other automatic transfer devices n'ihi ike ya, nke nwere ike ịgbatị ndụ ọrụ nke ndị nkịtị nkenke igwe na akụrụngwa.

Anyị nakweere nkenke oyi adọtara, honing na polishing iji rụpụta mkpanaka pneumatic cylinder hydraulic piston, ebumnuche teknụzụ ọ bụla na-ezute ọkọlọtọ mba.

Nkọwa nkọwa

Akụrụngwa: CK45 (GB/T699-1999)

Nkọwapụta igwe:

Ike tensile(Mpa):≥600N/mm2

0,2 Mgbalị Mpụ (Mpa):≥355N/mm2

Mgbatị: min.16%

Ọkpụrụkpụ Chrome Plated: φ<20mm≥15μm, site na 20mm na 20μm

Isi ike: Ra 0.2

oyi akwa Chrome siri ike: 850HV-1050HV

Nkwenye dayameta: f7,f8

kwụ ọtọ: <0.1um/1000mm

Ovality: 1/2 dayameta ndidi

Nyocha Corroseston: ISO 10289: 1999, IDT

Dayameta nke mpụta: 3-120mm (GCr15) 3-40m (SUS440C)

Ọnọdụ nnyefe: Nkịtị, Induction Harden, Q+T

Tebụl mejupụtara kemịkalụ

| NKWUKWU kemịkal(%) | |||||||

| Ihe onwunwe | C% | Mn% | Si% | S% | P% | V% | kr% |

| <= | |||||||

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0,035 | 0,035 | ||

| ST52 | <= 0.22 | <= 1.6 | <= 0,55 | 0,035 | 0,035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0,035 | 0,035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Dayameta | Ibu | Ndidi | Ndidi | Ndidi |

| mm | Kg/m | f7 (μm) | f8 (μm) | h6 (μm) |

| 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| 8 | 0.39 | -13--28 | -13--35 | 0--9 |

| 10 | 0.62 | -13--28 | -13--35 | 0--11 |

| 12 | 0.89 | -16--34 | -16--43 | 0--11 |

| 16 | 1.58 | -16--34 | -16--43 | 0--11 |

| 18 | 2.00 | -16--34 | -16--43 | 0--13 |

| 20 | 2.47 | -20--41 | -20--53 | 0--13 |

| 22 | 2.99 | -20--41 | -20--53 | 0--13 |

| 25 | 3.86 | -20--41 | -20--53 | 0--13 |

| 28 | 4.84 | -20--41 | -20--53 | 0--13 |

| 30 | 5.55 | -20--41 | -20--53 | 0--16 |

| 32 | 6.32 | -25--50 | -25--64 | 0--16 |

| 36 | 8.00 | -25--50 | -25--64 | 0--16 |

| 38 | 8.91 | -25--50 | -25--64 | 0--16 |

| 40 | 9,87 | -25--50 | -25--64 | 0--16 |

| 45 | 12.49 | -25--50 | -25--64 | 0--16 |

| 50 | 14.22 | -25--50 | -25--64 | 0--19 |

| 55 | 15.43 | -30--60 | -30--76 | 0--19 |

| 60 | 18.66 | -30--60 | -30--76 | 0--19 |

| 65 | 26.07 | -30--60 | -30--76 | 0--19 |

| 70 | 30.23 | -30--60 | -30--76 | 0--19 |

| 75 | 34.71 | -30--60 | -30--76 | 0--19 |

| 80 | 39.49 | -30--60 | -30--76 | 0--22 |

| 85 | 44.58 | -36--71 | -36--90 | 0--22 |

| 90 | 49.98 | -36--71 | -36--90 | 0--22 |

| 95 | 55.68 | -36--71 | -36--90 | 0--22 |

| 100 | 61.70 | -36--71 | -36--90 | 0--22 |

Kedu ihe bụ ụkpụrụ nnabata f7 na f8:

Oke nnabata nke f8 buru ibu karịa nke f7, na nrụnye na-adabere n'ogo mpaghara nnabata oghere dabara adaba.Dịka ọmụmaatụ, mgbe nha bụ isi bụ 10-18, f8 (-0.016,-0.034), f7 (-0.016,-0.027), ntụgharị nke ndidi abụọ ahụ bụ otu, oke nke f7 dị ntakịrị, yana nkwụsịtụ. nso nke nwụnye dabara dị obere.

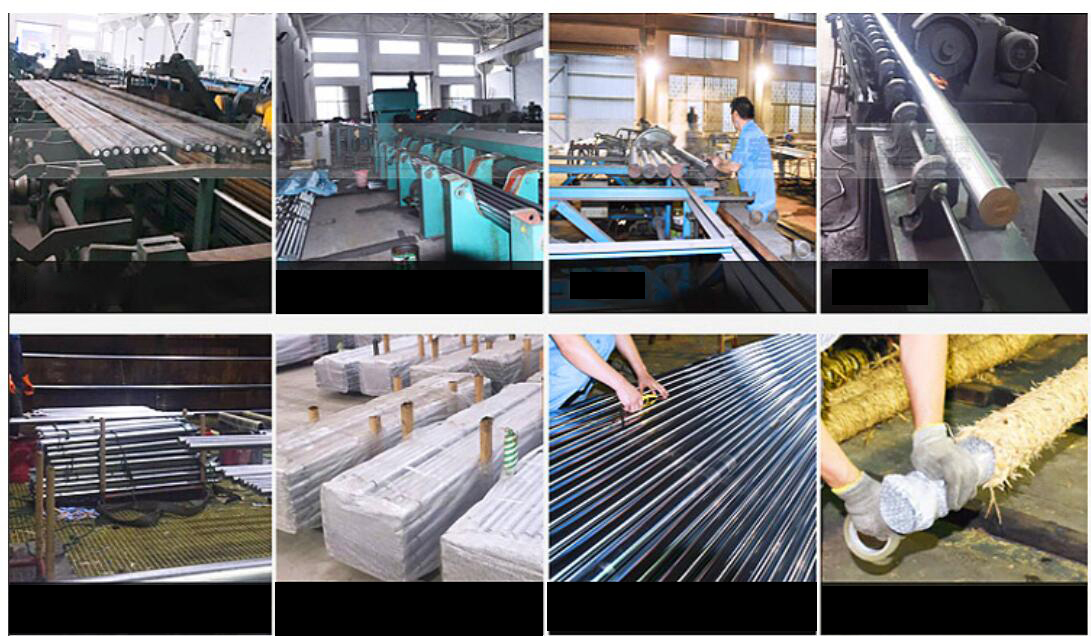

Usoro mmepụta

Nzọụkwụ 1: kpụpụ / oyi na-atụ:

Ihe osise oyi bụ teknụzụ nhazi nke mkpanaka piston pneumatic cylinder.N'ihi na pneumatic cylinder ike chrome plated mkpanaka, oyi ịbịaru na-ezo aka ịbịaru n'okpuru ọnọdụ nke nkịtị okpomọkụ iji nweta a ụfọdụ udi na ụfọdụ n'ibu Njirimara.Tụnyere na-ekpo ọkụ akpụ, oyi dọtara ngwaahịa nwere uru nke elu akụkụ ziri ezi na mma elu imecha.

2 Nzọụkwụ: kwụ ọtọ

Nzọụkwụ a anyị nwere ike ijide n'aka na mkpanaka chrome plated siri ike kwụ ọtọ zuru oke.Ọ dị ezigbo mkpa, mgbe wụnye ya insider na pneumatic cylinder.Ọkọlọtọ kwụ ọtọ bụ 0.2mm/m.

Nzọụkwụ 3: Ịkwado

Nhazi nke Honing bụ usoro nhazi nke ọma nke na-enyere aka pneumatic cylinder piston rod surface iji nweta oke nkenke, ịdị elu elu na ogologo ndụ.Ọ nwere ike melite nha nha nke ọma, na-akpụzi izi ezi ma belata uru Ra, mana ọ nweghị ike imeziwanye ọnọdụ oghere na ihe ndị ọzọ.

4 Nzọụkwụ: mkpanaka igwe na-ehicha ihe

Ntucha na-ezo aka n'iji igwe, kemịkalụ ma ọ bụ mmetụta electrochemical iji belata ịdị nro nke mkpanaka piston pneumatic cylinder iji nweta elu na-egbuke egbuke ma dịkwa larịị.Ọ bụ iji ngwaọrụ na-egbuke egbuke na ihe abrasive ma ọ bụ mgbasa ozi ndị ọzọ na-egbuke egbuke iji gbanwee elu nke pneumatic cylinder piston mkpanaka.

Nzọụkwụ 5: Chrome Plating

Chrome plating na-ezo aka n'omume ịkwanye chromium dị ka mkpuchi na mkpanaka pneumatic siri ike chrome plated.

Ihe mkpuchi chromium-plated nwere nnukwu ike siri ike, na ike ya nwere ike ịdịgasị iche n'ime oke 400-1200HV dịka nhazi nke ngwọta plating na ọnọdụ nhazi.Ihe mkpuchi chrome-plated nwere ezigbo nguzogide okpomọkụ.Mgbe okpomọkụ dị n'okpuru 500 ℃, ọ dịghị mgbanwe doro anya na gloss na ike siri ike.The okpomọkụ ga-amalite oxidize na-agbanwe agba mgbe okpomọkụ dị n'elu 500 ℃, na ekweghị ekwe ga-ebelata mgbe ọ bụ n'elu 700 ℃.Ọnụ ọgụgụ esemokwu nke oyi akwa chrome dị ntakịrị, ọkachasị ọnụọgụ esemokwu akọrọ, nke kachasị ala n'etiti ọla niile.Ya mere, oyi akwa chrome-plated nwere ezigbo mgbochi iyi.

Ihe mkpuchi chromium nwere ezigbo nkwụsi ike nke kemịkal.Ọ nweghị mmetụta na alkali, sulfide, nitric acid na ọtụtụ organic asịd, ma ọ nwere ike agbaze na pneumatic acid (dị ka pneumatic acid) na ọkụ sulfuric acid.N'ebe ọkụ a na-ahụ anya, ntụgharị uche nke chromium dị ihe dịka 65%, nke dị n'etiti ọlaọcha (88%) na nickel (55%).N'ihi na chromium adịghị agbanwe agba, ọ nwere ike ịnọgide na-egosipụta ya ruo ogologo oge ma dị mma karịa ọlaọcha na nickel.

Nzọụkwụ 6: Mkpanaka chrome plated na-ehicha ihe mgbe etinyechara ya

Electroplating na polishing: bụ ụzọ abụọ dị iche iche maka ọgwụgwọ elu nke ọla na ihe ndị ọzọ.Nke mbụ bụ ọgwụgwọ kemịkal, nke ikpeazụ bụ ọgwụgwọ igwe.

Electroplating: Usoro nke iji electrolysis iji tinye oyi akwa nke ihe nkiri igwe n'elu igwe ma ọ bụ ihe ọzọ.Ọ nwere ike igbochi corrosion, melite nguzogide eyi, eletriki eletriki, reflectivity na welie aesthetics.

Ntucha: Jiri ngwa nchacha na-agbanwe agbanwe na ihe abrasive ma ọ bụ mgbasa ozi ndị ọzọ na-egbu egbu iji gbanwee elu nke workpiece.Ntucha enweghị ike imeziwanye nha nha ma ọ bụ izizi geometric nke workpiece, mana ebumnuche inweta elu dị larịị ma ọ bụ enyo enyo.

Nzọụkwụ 7: Nnwale ogo nke mkpanaka chrome

Ogwe piston nke megoro electroplating na polishing usoro na-esonyere ya na ntụpọ mkpuchi dị ka olulu chrome na pitting.Ogo na ọnụọgụ nke ntụpọ ndị a na-emetụta kpọmkwem arụmọrụ nke mkpanaka piston.Iji belata mmetụta nke ntụpọ ndị a na mkpanaka piston, n'otu aka ahụ, site n'ịkwalite àgwà nke akụrụngwa, meziwanye nkà na ụzụ nhazi, na ibelata mmebi nke mmebi;n'aka nke ọzọ, ọ dị mkpa iji chọpụta n'ụzọ ziri ezi ntụpọ plating mgbe usoro polishing iji zere ngwaahịa na-erughị eru ịhapụ ụlọ ọrụ mmepụta ihe.Ndị injinia Autoair na-achọpụta nchọpụta ntụpọ akpaka site n'enyemaka nke ihe ọmụma sayensị onyonyo

8 Nzọụkwụ: mbukota

Ajụjụ:

Q1: Gịnị bụ pneumatic cylinder piston mkpanaka?

A: mkpanaka piston bụ ihe dị mkpa na nke dị oke egwu nke hydraulic ma ọ bụ pneumatic cylinder ọ bụla.Mkpanaka piston a bụ nkenke arụrụ ogologo ogologo chrome plated oyi a rụchara nchara nke na-ebunye ike piston mebere na akụrụngwa na-arụ ọrụ ahụ.

Q2: Gịnị bụ ụkpụrụ nke pneumatic cylinder piston mkpanaka?

A: The pneumatic cylinder piston na cylinder na-ebu mkpali ma ọ bụ dọta ike nke ikuku na-akpata, na-eme ozugbo na pneumatic cylinder piston mkpanaka ejikọrọ na piston, na mgbe ahụ, pneumatic cylinder piston mkpanaka jikọọ na ibu workpiece ịkwaga. azụ na azụ.

Q3: Gịnị bụ akụrụngwa nke pneumatic cylinder piston mkpanaka gị

A: Na-emekarị, pneumatic cylinder piston mkpanaka nke pneumatic cylinder ga-ahọrọ 45 # ígwè dị ka akụrụngwa.Ọ bụrụ na achọrọ iji cylinder emepụtara na mpaghara pụrụ iche, enwere ike iji igwe anaghị agba nchara 304

Q4: Gịnị mere họrọ 45 # ígwè dị ka akụrụngwa

A: 45 # ígwè bụ elu-edu carbon structural ígwè na ala ike na mfe ịcha.Mgbe emenyụchara, ike elu ya nwere ike iru 45-52HRC.Na ọ nwekwara ike inwe mma ịcha arụmọrụ na elu ike, siri ike na ndị ọzọ keukwu n'ibu Njirimara, ya mere, ọ bụ otu n'ime ihe ndị a na-ejikarị maka akụkụ aro.

Q5: Gịnị bụ machining usoro nke pneumatic cylinder piston mkpanaka gị?

A: Iji nweta ogo igwe kwụsiri ike, anaghị anabata nkwụzi aka nke mkpanaka piston ka ọ malitechara.Ya mere, a ghaghị ime usoro ịgbatị ahụ tupu ịmegharị.N'ihi nkwụsi ike na-adịghị mma nke workpiece, a ghaghị ime ntụgharị siri ike na ntụgharị dị mma n'oge usoro nhazi iji meziwanye nhazi nhazi.Ụdị ọrụ nke mkpanaka piston na-emegharị mmegharị ahịrị ahịrị.Iji meziwanye ndụ ọrụ nke mkpanaka piston, elu kwesịrị ịbụ chrome-plated iji meziwanye ike elu ya ma na-eyi nguzogide.Mgbe emechara chrome plating, a chọrọ ọgwụgwọ polishing iji nweta nhịahụ elu dị elu, belata ihe na-akpata esemokwu, wee kwalite arụmọrụ akara.Ebe ọ bụ na usoro polishing ahụ fọrọ nke nta ka ọ bụrụ mmetụta ọ bụla na dayameta mpụta nke mkpanaka piston, ọ dị mkpa ka arụ ọrụ ahụ nweta ịdị elu dị elu tupu chrome plating.Ya mere, ọ dị mkpa ịgbakwunye usoro nchịkọta nke ọma tupu usoro chrome plating (nkenke nkenke nwekwara ike imeziwanye nchikota elu nke chromium. ).Dabere na nyocha nke dị n'elu, usoro nhazi ihe ezi uche dị na ya maka mkpanaka piston bụ: ịgbatị-mgbanwe ntụgharị-nke ọma na-egweri-chrome plating-polishing.

Q6: Gịnị bụ polishing nke pneumatic cylinder piston mkpanaka

A: N'oge usoro ntụgharị, oghere etiti nke na-arụ ọrụ nke nhazi ga-egosi ọkwa ụfọdụ nke iyi.Iji hụ na ụkpụrụ dị n'otu nke akara akara, ekwesịrị ịkpụcha oghere etiti tupu egweri iji hụ na nhazi nhazi.Mgbe ị na-egweri, a ga-eme nyocha ule na gburugburu dị n'èzí dị nso na njedebe mbụ, na-egweri mkpanaka piston nwere ike ịme naanị mgbe ọnọdụ runout zutere ihe nhazi chọrọ.Na mgbakwunye na imeziwanye ihe ziri ezi nke akụkụ ahụ, usoro ịhịa ahụ dị mma dịkwa mkpa iji nweta oke elu dị elu n'elu igwe eji eme ihe iji meziwanye mmekọrịta nke ion chromium n'oge usoro electroplating.Iji hụ na ọkpụrụkpụ nke chromium plating oyi akwa nke ikpeazụ piston mkpanaka bụ edo, n'elu roughness mgbe ezi egweri kwesịrị ịdị nso n'elu roughness mgbe chromium plating na polishing.Ọ bụrụ na a na-achọ ka ọ dị elu nke mkpara piston ka ọ dị elu, dị ka Ra <0.2 μm, ọ ga-abụ nke ọma.Tinye nnukwu egweri ma ọ bụ polishing usoro mgbe egweri.