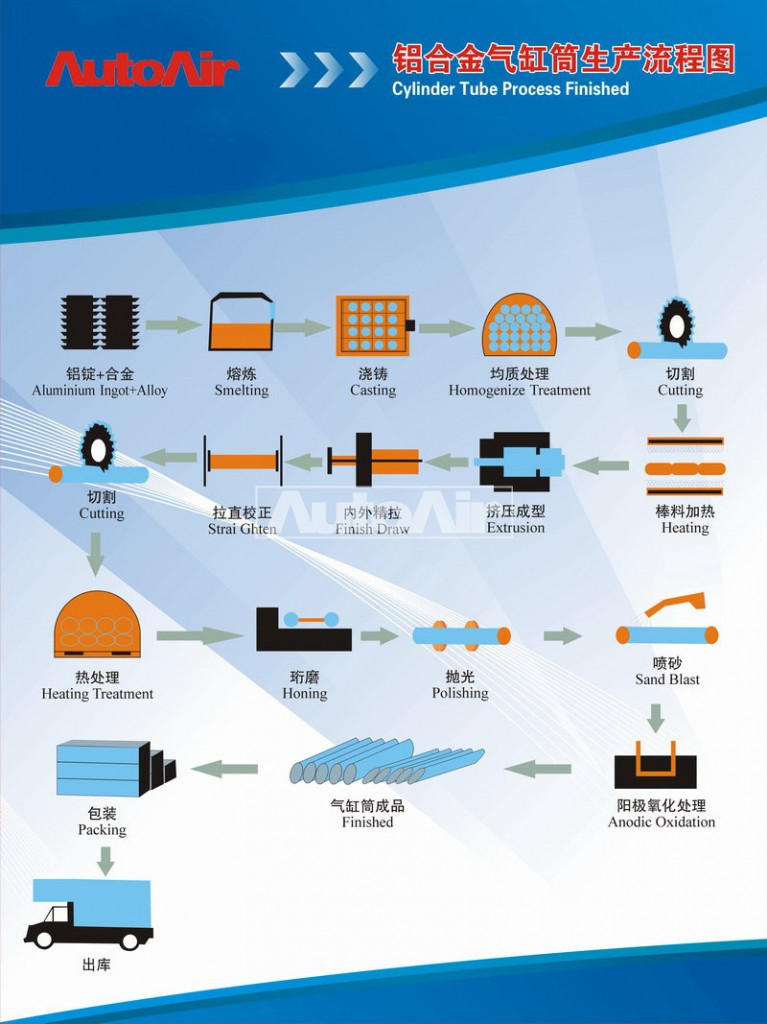

Usoro mmepụta nke Pneumatic Cylinder Tube

Ụlọ ọrụ ihe eji arụ ọrụ

Ụlọ ọrụ ihe eji arụ ọrụ

Ụlọ ọrụ Extrusion

Ụlọ ọrụ Extrusion

Mecha ụlọ ọrụ osise

Mecha ụlọ ọrụ osise

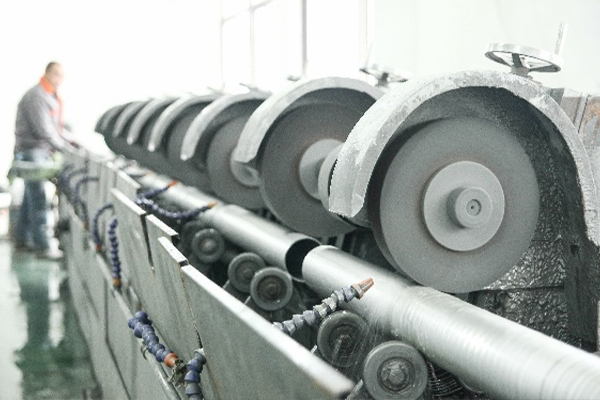

Ụlọ ọrụ Honing

Ụlọ ọrụ Honing

Ụlọ ọrụ Polishing

Ụlọ ọrụ Polishing

Ụlọ ọrụ mgbawa ájá

Ụlọ ọrụ mgbawa ájá

Ụlọ ọrụ Anodic Oxidation

Ụlọ ọrụ Anodic Oxidation

Mbukota pneumatic cylinder tube

Mbukota pneumatic cylinder tube

Ụlọ ọrụ ihe ejikerela

Ụlọ ọrụ ihe ejikerela

Nke mbụ, mgbe ị nwetasịrị eserese ahaziri nke onye ahịa ma ọ bụ onye ahịa na-anabata eserese ọkọlọtọ anyị, anyị ga-azụta akụrụngwa maka oghere ebu.

Nzọụkwụ 1:Profaịlụ aluminom extruded dị ka eserese site na ebu

2 tent nke igwe extrusion profaịlụ aluminom dị arọ

Nzọụkwụ 2:Mechaa eserese

Nzọụkwụ 3:Dozie

Nzọụkwụ 4:Ịcha

Nzọụkwụ 5:ọgwụgwọ kpo oku

Nzọụkwụ 6:Ịsọpụrụ

12 tent nke Pneumatic cylinder tube honing igwe

Ajụjụ:

Q1: Gịnị bụ honing?

A: Ịmecha nhazi nke imecha elu ya na whetstone (nke a na-akpọkwa osisi honing) agbakwunyere na isi honing.A makwaara dị ka na-agwụ ike.Ọ na-ahazi oghere cylindrical dị iche iche nke nwere dayameta nke 5 ruo 500 mm ma ọ bụ karịa, na nha nke omimi oghere na dayameta oghere nwere ike iru 10 ma ọ bụ karịa.N'okpuru ọnọdụ ụfọdụ, ọ nwekwara ike hazie ụgbọ elu, mpụga okirikiri elu, sppherical na-ebupụta, eze na-ebupụta, wdg. The elu gburugburu nke honing isi na-inlaid na 2-10 whetstones na ogologo nke banyere 1/3 ka 3/4 nke oghere ogologo.Mgbe ị na-agbanye oghere ahụ, ọ na-atụgharị ma na-aga azụ na azụ.N'otu oge ahụ, ọ na-agbasawanye nke ọma site na mmiri ma ọ bụ njikwa hydraulic na isi honing.Ya mere, ebe kọntaktị na elu nke oghere dị ukwuu, na nhazi nhazi dị elu.The akụkụ ziri ezi nke oghere mgbe honing bụ IT7 ~ 4, na elu roughness nwere ike iru Ra0.32 ~ 0.04 microns.The size nke honing ohere na-adabere oghere dayameta na ihe onwunwe nke workpiece, n'ozuzu 0.02 ~ 0.15 mm nke nkedo ígwè akụkụ na 0.01 ~ 0.05 mm n'ihi na ígwè akụkụ.The n'ọsọ ọsọ nke honing isi bụ n'ozuzu 100 ~ 200 rpm, na ọsọ nke re reprocating ije bụ n'ozuzu 15 ~ 20 m / min.Iji kpochapụ ihe ndị na-egbu egbu na ihe ndị na-eme ka ọkpụkpụ na-egbuke egbuke, na-eme ka ọkpụkpụ dị elu dịkwuo elu ma belata okpomọkụ nke mpaghara ịkpụ ahụ, a na-ejikarị mmiri ọkụ dị ka kerosene ma ọ bụ obere mmanụ spindle eme ihe mgbe ọ na-arụ ọrụ, na mgbe ụfọdụ a na-ejikwa emulsion nrụgide dị ukwuu.

Nzọụkwụ 7:Nchacha

2 tent nke elu polishing igwe

Nzọụkwụ 8:Mgbawa aja

2 tent nke elu sandblasting igwe

FAQ

Q1: Gịnị bụ ájá gbawara?

A: Usoro nke na-eji mmetụta nke elu-ọsọ ájá eruba ihicha na roughen elu nke mkpụrụ.A na-eji ikuku agbakwunyere dị ka ike na-etolite oghere jet dị elu iji fesa ihe na-agba (ọla kọpa ore, ájá quartz, ájá emery, ájá ígwè, ájá Hainan) na nnukwu ọsọ na elu nke workpiece ka a gwọọ ya, nke mere na a ga-agwọ ya. a na-agbanwe ọdịdị ma ọ bụ ọdịdị nke elu elu nke elu nke workpiece , N'ihi mmetụta na ịkpụ ọrụ nke abrasive n'elu nke workpiece, elu nke workpiece nwere ike nweta ụfọdụ ogo nke ịdị ọcha na dị iche iche siri ike, nke mere na A na-emeziwanye ihe ndị na-arụ ọrụ n'elu nke workpiece, si otú ahụ na-eme ka ike ọgwụgwụ nke ike ọgwụgwụ nke workpiece dịkwuo mma, ma na-amụba ya na mkpuchi The adhesion n'etiti n'ígwé na-agbatị ogologo oge nke ihe nkiri mkpuchi, ma na-eme ka ọkwa na icho mma nke mkpuchi.

Nzọụkwụ 9:Anodizing

2 tent nke anodizing ọgwụgwọ ahịrị

Ajụjụ:

Q1: Gịnị bụ anodizing?

A: Anodic oxidation, electrochemical oxidation nke ọla ma ọ bụ alloys.Aluminom na alloys ya na-etolite oyi akwa nke ihe nkiri oxide na ngwaahịa aluminom (anode) n'okpuru ọrụ nke etinyere ugbu a n'okpuru electrolyte kwekọrọ na ọnọdụ usoro akọwapụtara.Ọ bụrụ na akọwapụtaghị anodizing, ọ na-ezokarị aka na sulfuric acid anodizing.

Iji merie ntụpọ nke aluminum alloy elu hardness, eyi iguzogide na akụkụ ndị ọzọ, gbasaa ohere nke ngwa, na ịgbatị ndụ ọrụ, elu ọgwụgwọ technology aghọwo ihe dị oké mkpa akụkụ nke ojiji nke aluminum alloy, na anodizing technology bụ ugbu a. ndị kasị n'ọtụtụ ebe na-aga nke ọma nke.

Nzọụkwụ 10:Aluminom cylinder tubes emechara

Nzọụkwụ 11:Aluminom cylinder tubes mbukota